The art of transporting fresh air

Our flexible ventilation systems for mines and tunnels are among the most innovative in the world.

When Protan established Ventiflex in 1949, we were the first in Europe to supply flexible ventilation ducts for mines and tunnels.

Through almost 70 years we have gained extensive expertise and experience, which has created the foundation for today’s world-leading products and solutions.

Flame retardant and self-extinguishing

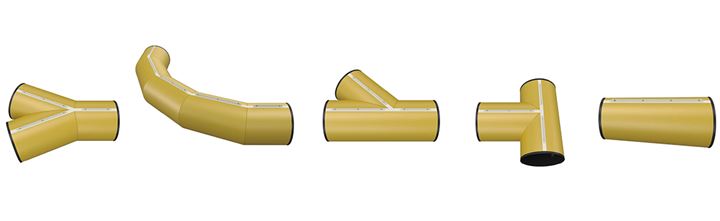

All our systems are custom-made to purpose for each project and supplied in five different qualities of ductings.

All five are flame retardant and self-extinguishing. In addition, two have anti-static qualities and are especially developed for environments in which flammable gases are present.

Driving force

We work continuously to drive the development of ventilation technology in mines and tunnels. We are a member of the NTN (Norwegian Tunneling Network) and we offer extensive training and user support to our Ventiflex clients. We maintain close dialogue and good cooperation with our clients, and training is included for installation, suspension and repairs.

Several hundreds of kilometres every year

Together with our collaboration partners, we supply several hundreds of kilometres of ventilation ducts to mines and tunnels every year. These are part of exciting and challenging projects in Nordic countries and the rest of Europe, South America, Asia, Africa and Australia.